DIY Truck Mod: OnBoard Air Compressor & Horn

This episode is a step-by-step guide to installing an onboard air compressor, tank, horn, and quick-connect air coupler, plus connecting the system to the factory auxiliary switches. We receive emails all the time asking for more details on where our compressor or horn is installed, and when recording installation videos at a truck modification shop, it’s hard to include all the key details.

Hopefully, this video offers the details the community has been asking for. Having onboard air is very nice for several reasons. The most beneficial is being able to fill your own truck and trailer tires. Especially if your tires are inflated above 65 PSI, which is where most gas stations stop. Another benefit is being able to use air pressure for annual winterization, but using the Viair Winterization kit. And of course using the air horn, which has countless applications!

Although train horns (and multiple horns) are more popular, I’m partial to the long single 25″ truck horn. Mostly because I don’t look good in orange and don’t want to go to jail! All kidding aside, I like having a horn that we can actually use. We’re not interested in causing an accident or scaring anyone. Plus, I like the sound of a deep dump truck.

Corrections:

You might have noticed that we initially wired the compressor to the auxiliary switch #2 and it ended up on #5. During our troubleshooting process, we wondered if the amperage was not high enough on #2 and moved it to #5 as switches 5 and 6 are the highest amperage. Then we discovered the real issue and bypassed the switch the kit came with.

You should know that auxiliary switches 5 and 6 can be adjusted to leave the power on when the truck is off. This is useful for things like a mobile fridge or anything that needs power when the truck is off. To do this, read your manual, but the unofficial explanation is to change the position of a fuse and viola!

We should have gone back and changed the switch we had Randy’s compressor connected to. Switch 3 or 4 would have been a better choice as they offer higher amperage, but would leave 5 and 6 vacant for future use. Oddly enough, Randy’s truck manual provided averages between 10 and 15 amps, which we know is not the case. We never got to the bottom of it.

Parts:

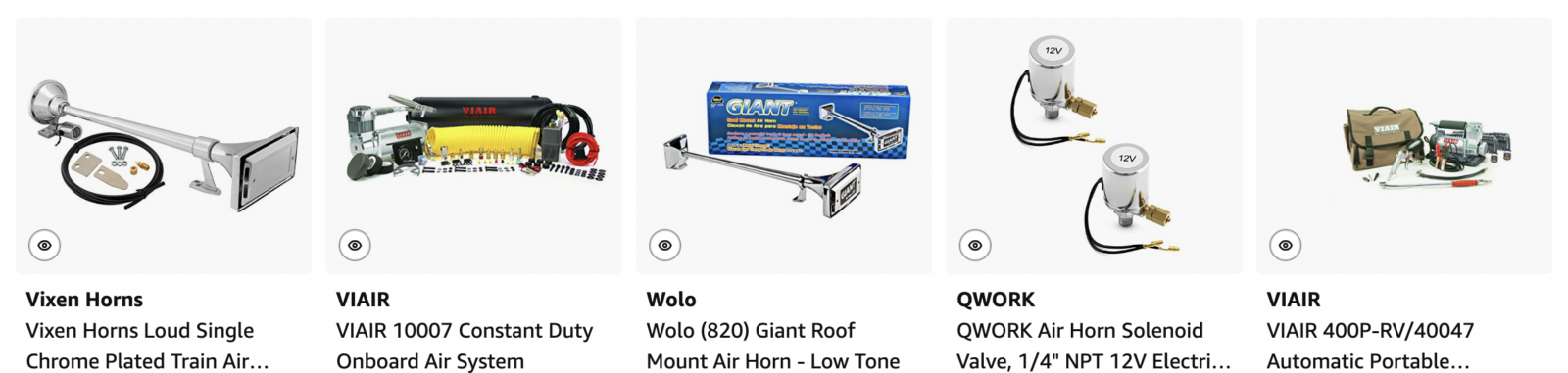

We updated our Amazon store “for your truck” category to include the parts used in this episode. The Viair Onboard Air System comes with everything you need. Make sure your horn comes with a 12-volt air valve solenoid, as it didn’t come with my Groover horn. The Vixen horn should sound just like my Groover horn for a quarter of the price. I bought my horn at a Kenworth dealership in 1998 for about $90 bucks. They’ve gotten pretty pricey!

I have a portable viair compressor, can it be used instead of the constant duty?

I want to add air bags to soften the ride on my F350 crew cab diesel 4wd long bed truck (2009) with 15,000 lb Warn winch and 90 gallon fuel tank/tool box in the bed. I know that a compressor and tank with female air quick connect fitting will be great. I will probably need to remove some or all of the heavy springs. Is there any kits that you know of that I can get installed?

I have the Klein air horns on my F250. I wired a relay on one of my aux switches that allows me to either honk factory horn or air horn using the horn on steering wheel.

Okay I watched this at least a dozen times. I’ll tell you what I know, but I know I don’t know it all. I have two Viair 444c compressors, they go through a water separator then to my 1.5 gallon tank. I highly recommend the separator as my tank is always dry. Get an air regulator and dial down the PSI, the lower the PSI to the horn the longer the horn will last. Buy a new air hose now, or better yet make one using flexzilla 1/4 ID hose. Those yellow coil hoses crack in cold weather, ya know when….just when you need it. Finally your QWORK solenoid, will last about a year, I have a WOLO 846 horn(think fire engine)It doesn’t come with a solenoid either. I’m using a HRS valve purchased on Amazon and i love it. Well good luck, I’ve enjoyed your video.

I have a 2023 F250 and I also installed the Viar continuous duty air compressor and purchased the vixen air horn same as Scott in the video. I have everything mounted/installed and compressor works great! Thanks for the info and lead on that.

I am struggling on wiring the horn to the upfitter switch. I did not get a wiring diagram with my horn. I requested it, but do t have it. I cannot figure out how to wire the two wires with “switch” on ground side. I am not an electrician. Just a DIY guy. Can you get info on how to wire that solenoid to the upfitter witch? I have searched everywhere and no one details how to wire it direct to upfitter. There is only info using a relay to replace the steering wheel horn after switching upfitter. I want mine the same as you have in video.